Correcting Distortion After Welding

Metal fabrication projects that use welding processes will usually experience at least some degree of welding distortion. Distortion in a weld results from the expansion and contraction of the weld metal and base metal during the heating and cooling cycle of the welding process. During the heating and cooling cycle, many factors affect the shrinkage of the metal and lead to distortion, such as physical and mechanical properties that change as heat is applied.

Distortion is an issue for multiple reasons, but one of the most critical is the potential of a weld that is not structurally sound. Welding distortions can threaten the structural integrity and/or the aesthetic of a project. Depending on the type and size of the distortion and the material used there are different corrective techniques that can be used to fix weld distortions.

The Many Forms of Distortion

Factors such as the type of metal, the amount of residual stress, and the degree of restraining used during the welding process impact the amount of distortion and the type of distortion. Here are some of the common types of welding distortions:

- Transverse Shrinkage - The weld distortions move vertically through the weld. The distortions are formed due to contractions that run perpendicular to the weld.

- Longitudinal Shrinkage - Shrinkage occurs perpendicular to your weld. The primary cause for this is applying force parallel to the weld.

- Angular Distortion - Occurs when stronger contractive force is applied on one side of the neutral axis. This causes warping or bending of the material in that direction.

- Bowing & Dishing - This occurs when the weld is not balanced along the neutral axis of the cross-section. The result is a curved shape.

- Buckling & Twisting - This is common among thin metal structures. It is time-consuming and difficult to rectify.

Techniques Used to Correct Distortion

- Hammering - This is the most common technique used to fix distortions. A hammer or power hammer is used to hit the distortion into a flat surface. This can be used in conjunction with thermal techniques to rectify many types of weld distortions.

- Heat Straightening - In this process, heat is applied to the distorted part using an oxyacetylene torch. The heating process followed by a natural cooling action can bring the deformation back into a more natural position.

- Hot Mechanical Straightening - Similar to heat straightening, but in this process, the metal is heated to the yield stress point. Heating metal to this point allows it to straighten and allows the physical appearance of the metal to be altered.

- Thermal Correction -Heat is applied to the distortion on the opposite side of the weld along a straight line. Line heating can be used to correct angular distortions. Heat can also be applied to small spots of the base metal to remove distortions on thin sheets.

- Hot Working - In this process, the heat applied surpasses the yield stress point. The metal is heated to the point that molecular changes occur. The metal will begin to glow a cherry red at the proper temperature and you are able to move the metal into the desired position.

Contact Our Machine Shop for Quality Metal Fabrication Services & More

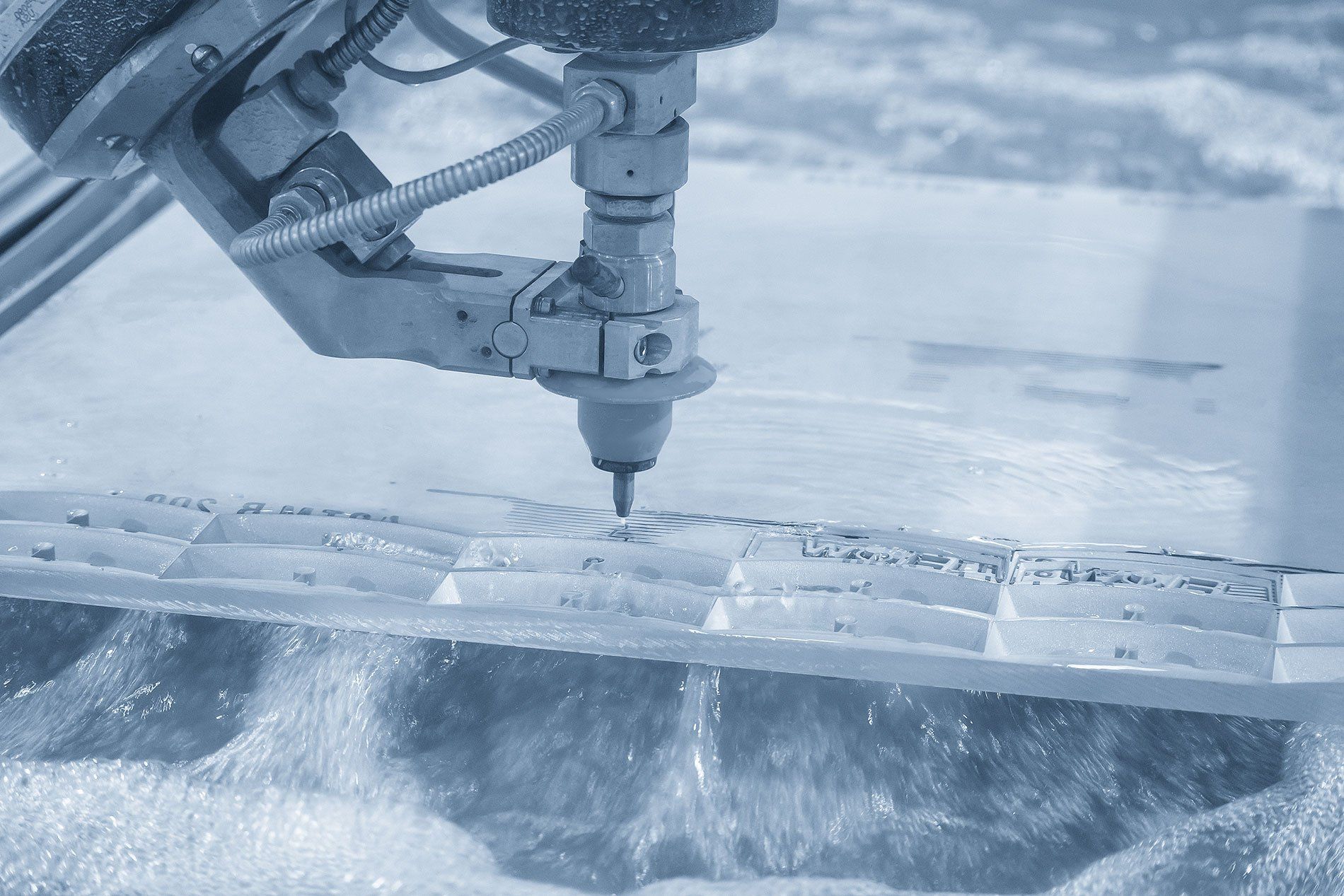

If you are looking for a reliable machine shop to assist you with a metal fabrication project, turn to Midland Waterjet. No matter your needs, we will handle everything from waterjet cutting, bending, and assembly, to welding. Our machine shop has the capability to work with a range of materials including steel, aluminum, copper, titanium, brass, cast iron, and so much more. For years, our machine shop has provided top-notch metal fabrication for clients across Midland, Odessa, Lubbock, Abilene, TX and the surrounding regions.

While we’re proud to offer quality metal fabrication solutions, we also have experience with stone, glass, wood, laminate, composite, and plastic fabrication services. If you’re interested in learning more, don’t waste another moment.

Contact our machine shop to get started on your next fabrication project!