Metal Fabrication Techniques That Increase Overall Value

The main difference between a standard and custom metal fabrication project is value.

From the initial design to the final delivery, the custom metal fabrication process aims to create durable, quality results with long-term value. Whether you run a commercial, industrial, or agricultural operation, it's important to maximize the value of your purchase by investing in high-quality items that work reliably and are built to last. Regardless of your custom metal fabrication project size or specifications, there are a few techniques that will help produce quality results with lasting value.

Establishing Design Intent

It's critical to clearly establish your preferred design and intent of your project if you want to achieve your desired outcome, which adds and retains the product's value. A custom fabricator can take any plan and flesh it out, creating a detailed design that will accomplish your project's goals and functions. In some cases, it will be necessary to refine and test the design to make sure that each individual component meets the requirements and regulations for the bigger project. Thoroughly planning your project leads to a completely customized, effective, and valuable final product.

Clearly establishing your design intent is especially important for custom metal fabrications such as:

- Material storage

- Liquid food storage for specialized conditions, such as containers with the ability to keep their contents at constant temperatures

- Custom metal pieces that have specific weight requirements

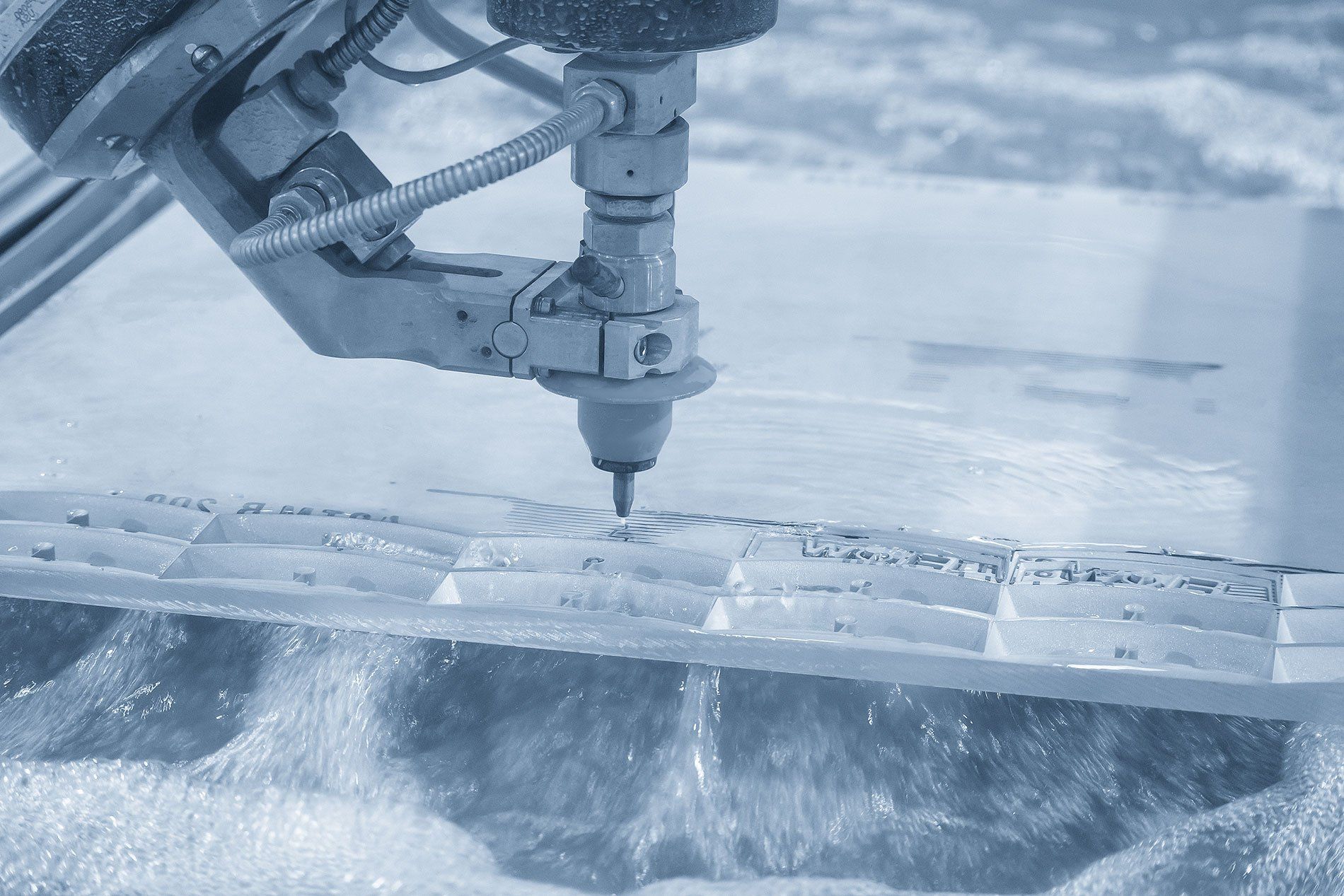

Metal Cutting & Shaping

There are many different metal cutting methods; The specific technique that is used for your project will depend on the type and thickness of the metal that needs to be cut. Some of the most well-known methods to cut metal include:

- Waterjet cutting, which uses pressurized water to issue precise cuts

- Laser cutting, which is most often used for delicate materials

- Plasma tables, which are most often used for carving circular holes or complex shapes out of thick metal

An experienced fabricator can assess the project and decide which methods are best suited to achieve the desired outcome.

In addition to cutting, most metal fabrication work often involves the fabricator to bend, roll, or punch the metal to mold it into the desired shape. By using the correct machinery and the best combination of shaping methods, the overall outcome is more likely to be successful.

Custom Welding & Assembly

Each custom metal fabrication product needs to meet specific project specifications and industry standards. In addition, quality control steps should be taken to ensure the fabricated piece works properly and effectively. When shipped, the components should be in their most complete form possible to ensure quick assembly upon delivery. These steps can drastically reduce your project's timeline and help to control expenses.

Certified welders are more likely to easily meet industry requirements, which ensures that your final product adheres to all necessary standards. If you have a custom metal fabrication project in mind, be sure to carefully choose your professionals to make sure that your final product is exactly what you want. The right welding professional will communicate closely with you throughout the duration of your project to make sure that your product meets or exceeds your specifications.

Expert Finishing With Value in Mind

The final finishing touches can help extend the life of any custom metal fabrication piece. It is a crucial step to ensure the product is resistant to corrosion, chemicals, and tarnishing. There are many finishing techniques for metal fabrication projects; the option you choose will depend on the piece itself.

- Metal Bead Blasting: This, along with other surface preparation techniques, prepares the metal surface for paint or other coatings. This allows the finished product to retain its color or finish for as long as possible.

- Custom Painting: We use controlled paint booths to ensure that the paint dries quickly and hardens as intended.

- Metal Powder Coating: If your metal product is more detailed, consider this technique to add a more decorative finishing touch.

- Hot-Dip Galvanizing: This type of finish coats every detail of the metal fabrication to protect it against moisture and help it retain its structural integrity.

By adding to your product's look and level of durability, the proper finishing technique can add a ton of value.

Have a custom metal fabrication project in mind? It's important to work with an experienced machine shop to make sure that you get the high-quality product you need quickly and efficiently! Rely on Midland Waterjet for expert service in the Lubbock, Abilene, and Midland, TX areas. Contact us today to discuss your needs! We look forward to working with you and creating a custom project that suits your needs and boosts value in every way possible.